Ok, might as well use a blog I already started to talk about stuff!

As a re-introduction, my name is Ben and I'm a student at Roosevelt High School. Here, like many places, seniors are tasked with completing a self-guided project (a "Senior Project," so creative a name).

My project was, originally, running my bike on an electric motor. I got bored with that idea, and decided to build an air engine, the sort of which you might have once seen on a powered airplane model. I acquired plans for a five-piston engine, and began to build it, but got distracted and bored yet again. Finally, I settled on something, and that's what this blog is now about.

A friend of mine from middle school became obsessed (to put it lightly) with replicating machines. He introduced me to the RepRap project some time in sophomore year, or something like that. Possibly earlier. In junior year, and he brought up the subject again.

I realized that Roosevelt High School was already positioned perfectly for launching into reprap production, and even had a laser engraver capable of cutting sheets of acrylic (sourced as FREE scraps from ever-awesome local businesses). Researching the topic is relatively easy, and there's a big community already in place (and growing) to look for news from.

Boom, RHS' TEClub* was born. We're a collection of students with varied interests in technology. At the moment we're working with

a local rep-strapper to convert our ProLight CNC mill into a three-six headed FDM beast. That was a bit more than a year ago now, and we've made serious progress (hindered by student laziness). We've got our machine "nearly working," which means... we need to build extruders, fix the firmware, and probably some other things that should have happened a year ago. We're also making a laser-based 3D scanner (someday we'll have software), and some other things.

Whoops, this post was about me, more on TEC later.

Anyway, after a half-year of TEC and one scrapped laser-cut Darwin, I realized I was now a senior. Time to kick it up a notch perhaps. As I stated earlier, my senior project ideas were pretty crazy. With help from best friend Griffin (original introducer), I decided to aim even higher and build my own 3D Printer. The darwin parts were done, but the price on the non-lasercut parts was too high. That's when I found the

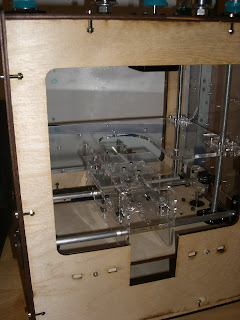

Makerbot Cupcake CNC. A simple printer, less print area than the Darwin or later Mendel, and a huge price tag. However, I realized that I could probably get all the parts locally, and a large part for free.

The plywood was mooched out of TEC's supplies, and laser cut for free. That and the free acrylic provided me with 50% of the parts (by volume). As for the electronics, well, I knew how to solder, and so I simply ordered the PCBs alone and over time ordered the components from Mouser and Digikey (a note about this later!). As for the other parts, well, I have Tacoma Screw nearby to go to for cheapish nuts n' bolts, and Harwicks' for other parts.

After thinking about it, I decided to improvise wherever a component would cost too much(more than $50, I'm cheap), and so I have a custom $10 X-Y stage from aluminum rod and brass tubing, and I've been designing a laser cutting pulleys for belts taken from printers. Actually, it was Griffin that did the designing for the first pulleys on Z. They work great.

That note about the electronics? Yeah, never, ever order $40 in crucial parts via usps just because they are the cheapest! It's been three weeks, and they're still in the mail!

March 7th, and the electronics are nearly done (grr), the frame is complete, and the X, Y, and Z stages need little more than their pulleys to be cut out. The extruder is non-existant, and I need to build the entire thing - luckily, I have a laser cutter.

That's all I can write for today, but I'm going to go submit this to the aggregated reprap and makerbot blogs. G'night all.

* Depending on who you ask, this is either "Tacgnol" or "Torchwood" Engineering Club... Club.

The other thing from last week wa

The other thing from last week wa

Next up, I finally discovered why my package from Digikey was taking so long... I had supplied the wrong address! The keys 9 and 6 are hard to accidentally interchange, but what can I say? I re-ordered and the package arrived last monday (yesterday as of writing). I gathered up everything I thought we would need and carried it all over to Griffin's to solder the last parts onto the boards. Great success! They're looking nice, and the only thing that has an issue is the big resistor on the motherboard. It's there to put a load on the PSU to get it to turn on (talk about an odd safety system). Sadly, we got a 5W .30ohm resistor... the machine needs a 5W 30ohm one. Whoops. We also have a 5W 3.0ohm resistor, so thi

Next up, I finally discovered why my package from Digikey was taking so long... I had supplied the wrong address! The keys 9 and 6 are hard to accidentally interchange, but what can I say? I re-ordered and the package arrived last monday (yesterday as of writing). I gathered up everything I thought we would need and carried it all over to Griffin's to solder the last parts onto the boards. Great success! They're looking nice, and the only thing that has an issue is the big resistor on the motherboard. It's there to put a load on the PSU to get it to turn on (talk about an odd safety system). Sadly, we got a 5W .30ohm resistor... the machine needs a 5W 30ohm one. Whoops. We also have a 5W 3.0ohm resistor, so thi That brings me to the next item I want to talk about! I read

That brings me to the next item I want to talk about! I read